Hayward Field Renovation.

REFA Completes Hayward Field Renovation at University of Oregon.

Eugene, Oregon

A project like Hayward Field Renovation only comes around once in a lifetime. Steeped in a rich 100-year history Hayward Field has become the nation’s most storied track and field venue. Hayward Field has been the home of legends since its inception. Named for the father of Oregon track and field, and one of its most innovative early coaches, Bill Hayward (1904 – 1947).

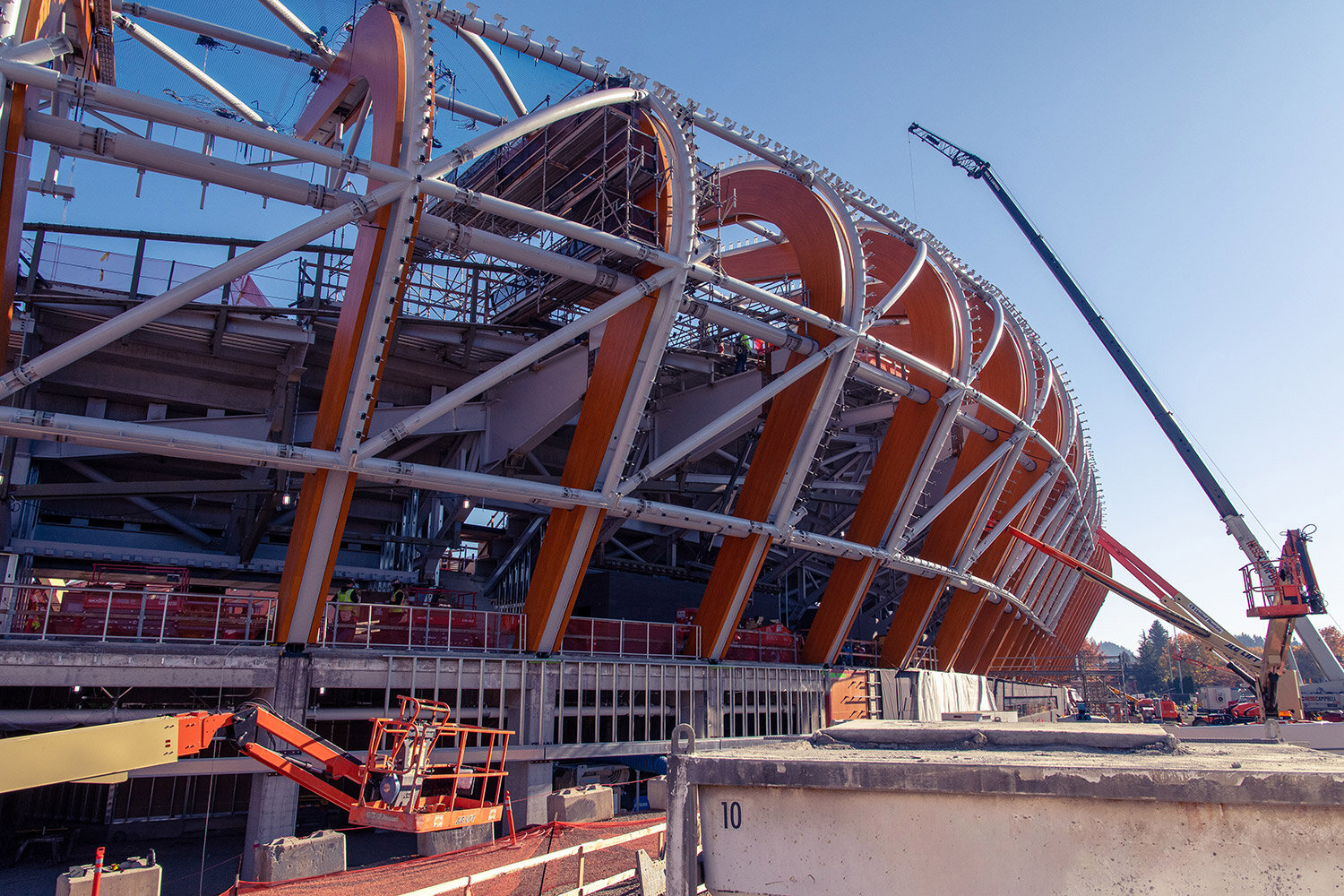

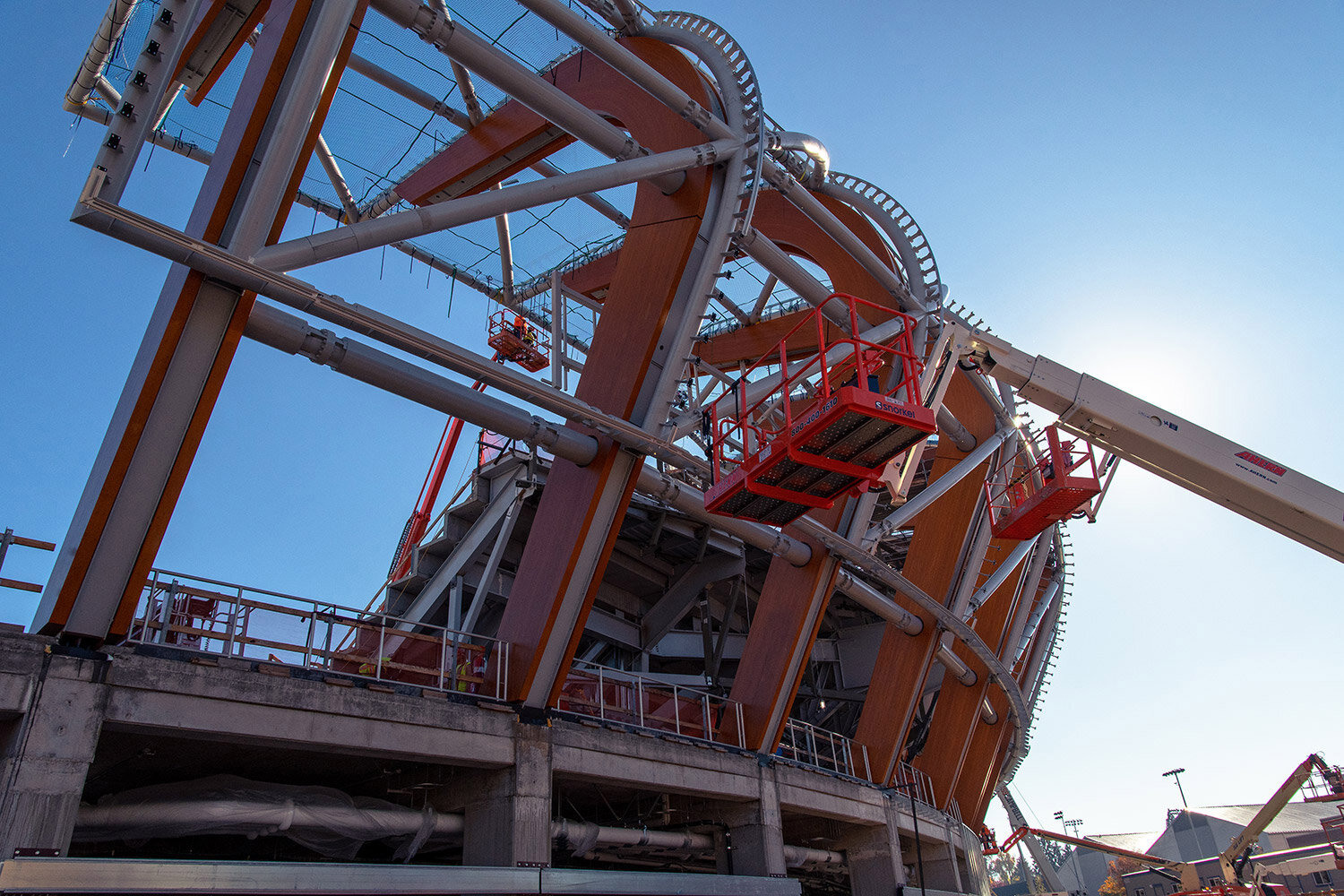

The architecture of this new track and field “theatre” is advanced, with multiple interwoven layers. It has a capacity of 12,650 permanent seats, with the option to expand to nearly 25,000 seats. At the core, and supporting the majority of the weight are 50 raker trusses and 77 curved steel bents. Each bent repeats evenly, morphing slightly in scale, following the geometry of the track. Intended to create a heroic wood roof structure, these steel bents are capped on both sides with Douglas fir glue laminated beams, a tribute to Oregon history, culture, and forest products.

Stitching it all together on the outside of the bents is a complex web of curved steel pipe called the diagrid. The diagrid consists of 539 individually rolled 14” pipe sections welded and bolted together. The diagrid interfaces with an aluminum extrusion, and tension cable system stretching a Texlon ETFE (ethylene tetrafluoroethylene) translucent silver membrane over the diagrid structure, the final outer skin of the stadium.

Needless to say when REFA Erection, Inc. (Tigard, OR.) was invited to bid on this landmark project, they didn’t hesitate to enter the race. Once the contract was awarded to REFA, their teams quickly got to work. Expectations of the owners were high. Workers had to come together on an accelerated timeline, and create a world-class track and field facility by May 2020. A myriad of factors and details had to be taken into consideration. A structure of this scale and complexity with 32 erection sequences, would present many unforeseen challenges.

After months of careful planning REFA contracted with longtime trusted partner Ness Campbell Crane. REFA and Ness Campbell worked to ensure the right mix of cranes and rigging were being used. Six cranes were on site: (2) 2250’s, (1) 16,000, (1) 160 ton, (2) 130 ton. REFA’s ironworkers and Ness Campbell’s operators worked together seamlessly as a team to achieve the monumental task of safely, and efficiently hanging all the complex iron on schedule.

The first pieces of steel to arrive in two upper and lower sections were bents. Once assembled the huge curved pieces were approximately 50 feet to 85 feet tall, ranging from 12,000 lbs. up to 40,000 lbs., respectively. REFA had to fabricate a custom table jig to ensure proper fit-up prior to welding the sections together. There was a collection of 10 welders working to complete the task. Once the welds were completed, a thorough UT was performed by the inspectors. Bents then had to be moved away from the table area, sand blasted, and brought back to the table for paint. A custom engineered spreader bar was fabricated to lift the bents at their fulcrum point. This custom assembly in addition to stabilizers at the base was necessary for full control.

Raker trusses started to filter on site, ranging from 5,000 lbs. to 30,000 lbs. The raker trusses connect the bents and bowl steel, and support the majority of the weight from precast seating. REFA ironworkers used porta powers and guy cables to manipulate raker’s into their final position on the grid. Rigging had to be precise, coordination between REFA’s raising gang and bolt up hands was essential to correct placement.

Total Station was an indispensable tool used in the field to ensure bents, rakers, and bowl steel were on grid and set at the proper elevation. Once position was established, Total Station’s prism reflector was placed on each step of every raker truss for positive verification.

At the height of the project REFA employed 50 workers on days and 50 on nights. Five raising gangs worked on an accelerated timeline moving 5,100 tons of steel. A total of 77 bent pieces, 50 raker truss pieces, 539 diagrid pieces, 462 curved glulam pieces, 426 pieces of precast, and 104 union ironworkers who safely got the job done. Let the games begin!

Get a birds eye view of the project shot with a drone for our partner Ness Campbell.

REFA Steel Erectors is excited about being part of this historical, world class renovation.

Contact us today to bid on your next steel project.